offering bespoke solutions to serve your equipment needs

Malin Equipment offering: Naval base & Shipyard equipment Port & ferry equipment Advanced projects

Our specialist engineering team offer a range of marine equipment – from off the shelf products, to individually designed, bespoke solutions, each tailored to our clients specific requirements and delivered to meet their exacting standards. The Malin Equipment team are also on hand to offer a consultancy service, drawing on the teams expansive experience and expertise. Serving a range of clients, across geographies and industries, notably defence, submarines and subsea, our access to Malin Group’s wider design resources, combined with our team’s extensive record to date, has enabled our team to deliver a range of customised solutions. From naval bases and shipyards, to ferry and vessel owners, operators, and ports, our clients have harnessed our expertise to procure a series of optimised solutions, as we support them from design and development, to manufacture, delivery and installation – a truly turnkey service.

With a combined experience of over 100 years, our core team of five features engineers, naval architects and project managers – each well versed in the delivery of complex marine projects, whether newbuild or retrofit and recertification in nature. Our on-site support team can also provide both warranty support and through life maintenance services.

We are committed to safety and risk management at all stages of a project from concept, through to detailed design and implementation to deliver a fit for purpose solution. We hold ISO 9001, ISO 14001 and ISO 45001 accreditation with DNV GL and our fabrication colleagues are accredited with ISO 1090-1 Execution Class 4 and ISO 3834-2. Our IT systems are protected and accredited to Cyber Essentials Plus.

We are also passionate about collaboration, sharing best practice and providing progressive, innovative solutions, with in-house collaboration with our Malin Skunks team. We are members of a variety of industry bodies and best practice sharing groups and societies, and regularly work with all major classification societies.

a spotlight on our hydraulic keel blocks

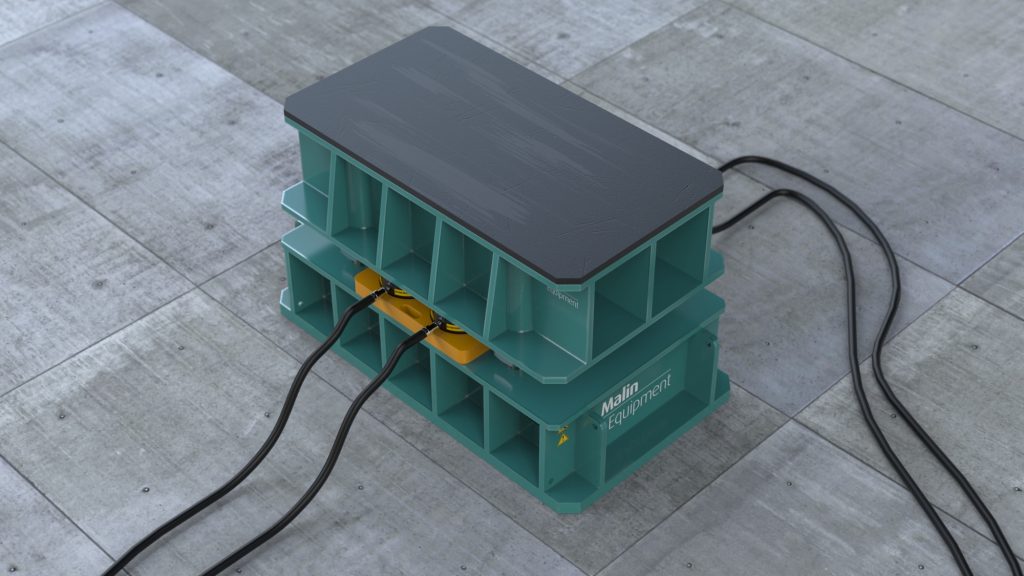

Traditionally keel blocks have been made from timber, steel or concrete, often using a mix of multiple materials as packing, to create a level platform on which to rest the ships keel. One of the many challenges faced by shipyards and ship builders is that, during construction and/or maintenance, individual keel blocks may need to be removed or repositioned to access a particular section of the keel or hull for inspection or maintenance. The process of keel block removal is not straightforward, and even once removed, repositioning also poses a completely new set of challenges. With that, we have developed a removable keel block.

Manufactured from high strength steel, the blocks can be designed to meet specific customer requirements – but the fundamental principle remains the same. Each block is made of two halves: A base, designed to distribute vessel loadings into the dock floor; and a top designed to tie in with structural framework and bulkheads for effective load distribution. Connecting these two halves is then a set of adjustable screws, and location points for heavy load hydraulic cylinders. Principally the system is mechanical however adjustment and removal is achieved through the use of heavy lift cylinders. This innovative design facilitates the complete removal of an individual keel block while also providing the ability to record the installation load, so that, when reinstalled, the load can be reinstated to its pre removal value. When reinstalling a keel block that has been previously removed, the operator only needs to ensure that the hydraulic cylinders are pressurised/loaded to the pre removal value, prior to tightening the load bearing and locking nuts. This ensures that previous loading in adjacent keel blocks is also restored, maintaining a more even load distribution within the keel, the keel blocks and dock floor.

ADJUSTABLE

DESIGN

HEIGHT

FINISH

EXTRAS

DURABLE

STRENGTH

Bespoke solutions including: Surface Ship and submarine docks and cradles Catamarans Buoyancy Assist Module (BAM) Upender Ramps Linkspans Passenger Access Systems Wingsail build, mobilisation and demobilisation Archimedes Wingsail Engine lifting Antonov Cradles

Malin Equipment offer expertise and experience across a range of sectors and specialism, with a proven track record of delivering value add bespoke equipment solutions.

Equipment to us is more than the simple supply of off the shelf items. No matter the size or scope of your project, our team of engineers assess your needs and propose optimum solutions. All initial consultations are free of charge – simply contact us to find out more.